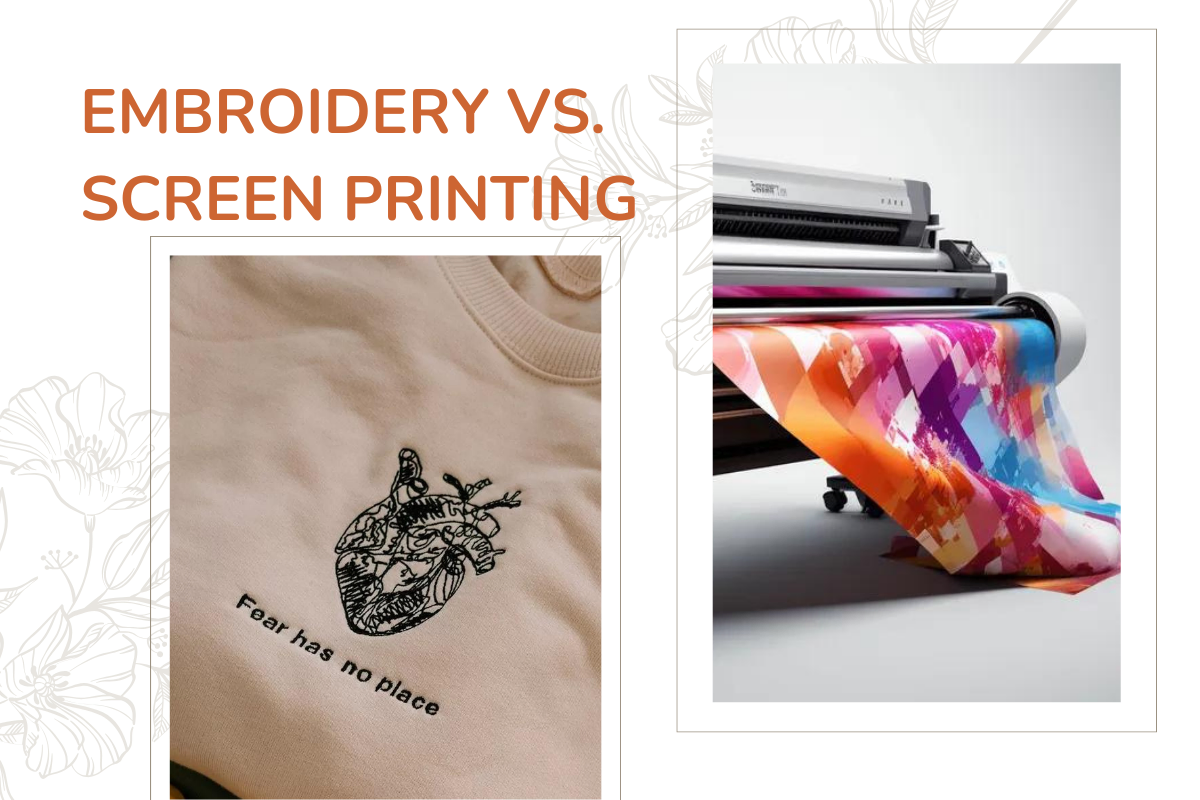

Embroidery vs. Screen Printing: Which is right for you?

When exploring the realm of print-on-demand, you frequently encounter a pivotal choice: embrace the enduring sophistication of embroidery or embrace the vibrant, modern allure of screen printing? These decisions fundamentally shape your brand’s visual identity.

If you’re struggling to decide between these distinctive techniques, fear not. We’re here to navigate you through the intricacies of embroidery and screen printing, assisting you in identifying the method that aligns best with your requirements.

Embroidery

Embroidery, from mending torn garments to stitching intricate patterns, has long been a staple in the fashion world. Let’s delve into the specifics of embroidery and its production process.

What is embroidery?

Embroidery is the art of decorating fabric or other materials using a needle and thread. Originally a handcraft, modern techniques often employ machines for embroidery, significantly reducing the time required for complex designs and enabling mass production. However, traditional hand embroidery remains an option for those wanting to explore their artistic side, allowing for various thread and yarn thicknesses, as well as the addition of colorful beads, sequins, and other embellishments.

How does embroidery work?

Whether done by hand or machine, embroidery involves transforming simple materials into elaborate, textured artworks. Here’s a step-by-step guide to modern machine embroidery:

- Prepare the design: Upload a compatible digital version of your design/logo/text for the embroidery machine to process. The better the compatibility and quality, the more accurate your embroidered logos, designs, or text will be.

- Choose the fabric: Selecting the right fabric is crucial, as its density and texture can affect the thread’s performance and the overall pattern consistency.

- Pick the thread: Different types of threads create different textures and appearances. Options range from cotton to metallic fibers, allowing for a variety of finishes.

- Decide on colors: The thread colors and materials significantly impact the design’s aesthetic. At Printful, for example, unlimited color options are available, making gradient designs possible.

- Choose the stitch type: Select a stitch type that complements your design, whether it’s a flat design or a 3D puff.

- Secure the shirt: Ensure the fabric’s design area is securely fixed under the embroidery machine.

- Embroider the design: Securely hoop the thread to ensure a stable and taut embroidery process. The machine, using needles and bobbins, then stitches the design onto the fabric. The speed and accuracy depend on the machine’s precision and the number of stitches per minute.

Embroidery, with its rich history and modern advancements, offers a timeless, sophisticated touch to any fabric. Whether you choose traditional hand methods or modern machine techniques, the results are invariably impressive.

Screen printing

Traditional screen printing has roots dating back to the Song Dynasty (960–1279 AD), when the Chinese crafted the early model of silk screening. But what exactly is it, and how does it work? Let’s walk through the screen printing process step by step to help you choose the right customization method for your apparel.

What is screen printing?

Screen printing is a printing method that uses ink, a mesh screen, and a stencil to create vibrant, high-quality prints of your desired design. Its durability and versatility have made it popular in the printing and fashion industries, allowing for high-quality prints on various materials. Screen printing is often favored for bulk orders, producing vivid graphics on apparel, posters, and other products.

How does screen printing work?

To help you decide if screen printing is the right method for your production needs, let’s delve deeper into how it works:

- Design preparation: Begin by preparing your design and selecting the appropriate inks for the final print.

- Screen creation: Specific screens are developed for the entire design or individual layers of your design. The more detailed and complex the design, the more screens are necessary for different colors and layers. A popular way of creating the stencils is by applying an emulsion to the mesh screen, which is then left in a dark room to dry.

- UV light exposure: Once the screen is prepared, place the design paper on top and expose it to UV light, which permanently hardens the emulsion. This ensures that the ink passes through the mesh screen, creating the design.

- Ink transfer: The ink is transferred onto the fabric through the custom mesh stencil using a special tool called a squeegee, printing your design onto the apparel.

- Layers: For complex designs with multiple layers or colors, repeat the process for each layer. Each layer must dry before applying the next one.

- Drying time: Allow the ink to dry completely, depending on the complexity of your design.

Screen printing is a detail-oriented and intricate process, making it time-consuming. However, the durability and vibrancy of the resulting prints make it worth the effort.

Embroidery vs. Screen Printing: Key Differences

Let’s explore the specifics of embroidery and screen printing. As we examine each method, consider the details that might reveal which technique better suits your needs.

Durability

Embroidery: Embroidery offers lasting durability and resistance to fading or color loss over time. Designs remain intact even with frequent washing, as closely stitched threads create a robust bond with the garment, preserving the integrity of your designs.

Screen Printing: Screen printing also offers lasting durability, but frequent washing can cause colors to fade and quality to diminish over time.

Texture

Embroidery: Embroidery provides a raised texture with different stitching patterns, making it ideal for small and intricate designs like logos. It is popular for classic and preppy wear, uniforms, or luxury clothing.

Screen Printing: Screen printing creates a smooth, flat design surface, suitable for a modern look such as streetwear, casual wear, or sports apparel. It is well-suited for large designs, including large logos. While it does not match the texture of embroidery, layering ink in screen printing can achieve a somewhat raised effect.

Color Variety

Embroidery: Embroidery may face limitations in color availability depending on the production facility, as it relies on existing thread colors. This makes it more suitable for designs that fit within the available palette. However, partnering with us alleviates this issue, as they offer unlimited colors to choose from, ensuring your embroidered design closely matches your original vision.

Screen Printing: Screen printing offers more flexibility in design choices, as inks can be mixed to achieve a wide range of colors. This allows for greater creativity and precision in matching your desired color scheme.

Fabric Compatibility

Embroidery is compatible with a wide range of fabrics, including linen, denim, crepe, and velvet, making it ideal for fashion styles that prioritize durability and texture. However, it is not suitable for waterproof clothing like raincoats or diving suits due to the needle holes involved in the process. Embroidery is particularly effective for items such as caps, scarves, and polo shirts, where a premium, textured appearance is desired.

Screen Printing, on the other hand, is not suitable for stretchy or uneven fabrics, which can affect print quality and clarity. It performs best on natural fabrics such as cotton, linen, or blends, and is commonly used for t-shirts and hoodies. This method ensures a smooth and flat design surface, ideal for achieving clean, vibrant prints.

Small Details

Embroidery offers precision for small, intricate details, making it ideal for texts, company logos, and other fine elements. It is particularly well-suited for designs where detail and texture are crucial, providing a high level of accuracy and craftsmanship.

Screen Printing can effectively replicate larger designs closely to the original. However, it may not capture every detail as precisely as embroidery, especially upon closer inspection. It is suitable for designs featuring color splashes or large graphics, although individual prints may exhibit slight variations.

Order Quantity

Embroidery is cost-effective for both small and large batches, making it ideal for newcomers to e-commerce. You can order just one custom embroidered garment from EmbroInk without incurring significant risk, allowing for flexibility and experimentation.

Screen Printing involves high setup costs, making it cost-effective primarily for bulk orders. This approach can be riskier for e-commerce beginners due to the need for large quantities to achieve economical pricing, which might not be suitable if you are just starting out.

Look and Feel

Embroidery: Embroidery creates a premium look and feel with raised textures and various patterns. It offers a handcrafted, sophisticated appearance, making it ideal for luxury or classic styles.

Screen Printing: Screen printing provides a smoother and flatter texture, delivering a clean, polished look. It is suited for a modern and bold aesthetic and is comfortable to wear even with large design areas.

Care and Maintenance

Embroidery: Embroidered garments require more care and maintenance due to their intricate threads and patterns. It is essential to turn these garments inside out to protect the design and avoid washing them with sharp objects that may snag the stitching. Despite the need for extra care, embroidered items are more suitable for frequent washing and drying compared to screen-printed clothing.

Screen Printing: Screen-printed garments should be handled with care to maintain print quality. Avoid high temperatures and harsh detergents, as these can damage the print. To prevent staining, it is important to separate colors and whites before washing. Gentler washing methods are recommended to preserve the vibrancy and durability of the screen-printed designs.