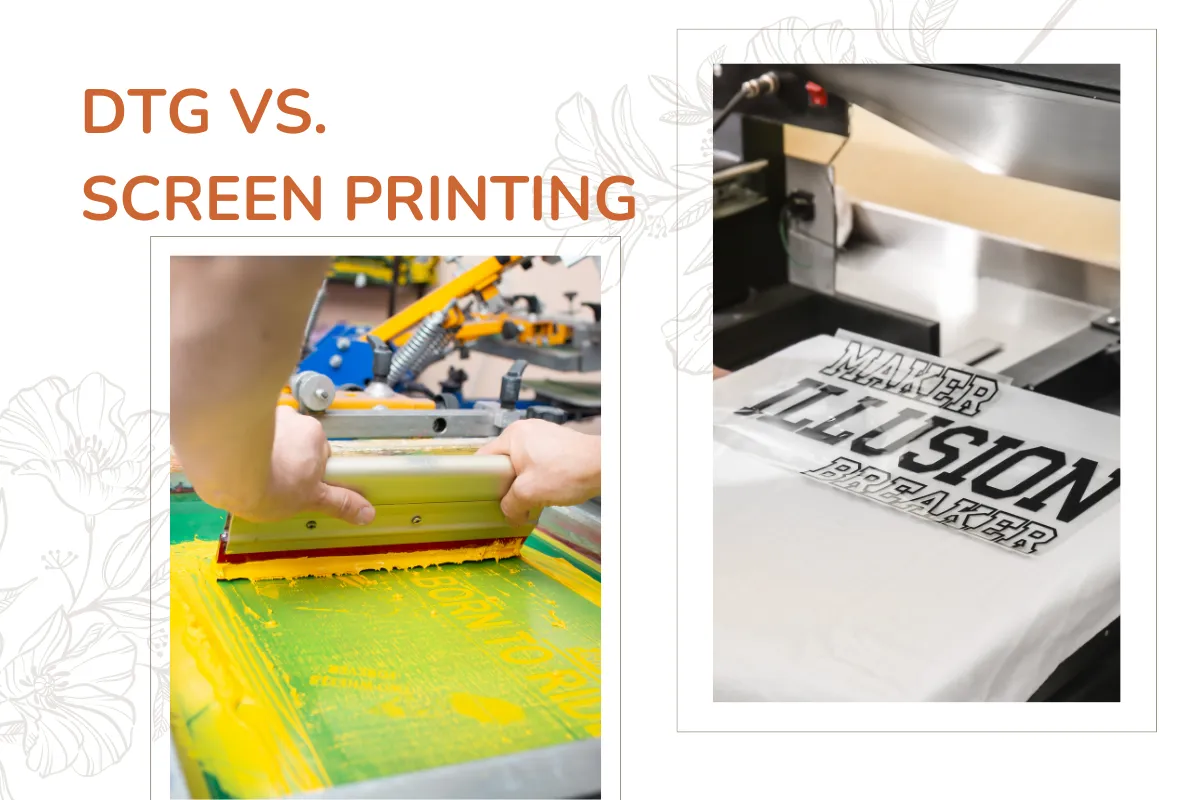

DTG vs. screen printing: Which printing method is better?

When deciding between Direct-to-Garment (DTG) printing and screen printing, it’s essential to understand the key differences and the scenarios where each method excels. DTG printing stands out for short print runs, producing sharp, detailed images, and being a more sustainable option. In contrast, screen printing is often the preferred choice for larger print runs and offers superior durability. To help you make an informed decision on which method suits your needs, let’s delve into the details of screen printing and why it might be the best choice for certain projects with EmbroInk.

DTG vs. screen printing

Origins of Screen Printing

Screen printing, also known as silk screen printing, has a rich history dating back to 1907 when Samuel Simon patented it in England. Initially, it was primarily used to apply vibrant colors and intricate patterns to fabrics and wallpaper. Its versatility and effectiveness quickly caught the attention of advertisers, and it soon became a popular method for creating eye-catching promotional materials.

What is Screen Printing Used For?

The flexibility of screen printing has led to its widespread use in various applications. You have undoubtedly encountered numerous screen-printed items in your daily life, such as:

- Clothing: Most printed T-shirts, uniforms, jackets, and other apparel are produced using screen printing.

- Containers: Specialized equipment allows screen printing on glass and plastic containers, like shampoo bottles.

- Media: Nearly every CD and DVD with an image utilizes the screen printing process.

- Fine Art: Screen printing is also favored for creating fine art prints.

The reason behind the diverse applications of screen printing lies in its ability to deliver bold, opaque colors on a wide array of materials. Different ink formulations enable specific inks to bond effectively with materials such as glass, plastic, and metal, resulting in vivid and durable images or messages. This makes screen printing a reliable choice for producing high-quality prints in large quantities.

Despite the advancements in technology and the rise of digital printing, screen printing remains the preferred method for many printing applications due to its reliability, versatility, and ability to produce long-lasting, high-quality results.

Origins of DTG

Direct-to-garment (DTG) printing is a modern method of producing T-shirts that employs a special digital printer to apply water-based inks directly onto fabric surfaces. Unlike traditional printing methods that require screens or transfer paper, DTG printing transfers inks directly onto the T-shirt surface, streamlining the process and enhancing image quality.

DTG printing acquires images from digital files, allowing printers to reproduce virtually any color with high resolution and sharpness. This method is versatile and can print on popular T-shirt fabrics, including cotton, polyester, and cotton/polyester blends, although it performs best on natural fabrics like cotton.

One of the standout features of DTG printing is its eco-friendliness. It relies on water-based inks and can print on organic cotton, making it a sustainable choice. Additionally, because DTG prints directly from digital files, it can handle any quantity, from single units to larger batches, providing flexibility for various needs.

While DTG printers can be costly, with prices often exceeding $10,000, small businesses and entrepreneurs don’t need to own one to utilize DTG printing services. This accessibility makes DTG printing an affordable option for producing high-quality, custom T-shirts.

DTG vs. screen printing: Which printing method is better?

Screen printing became popular for T-shirt production in the 1970s and remains widely used. However, it is time-consuming to prepare stencils and screens, making it inefficient for smaller print runs. Today, screen printing is often reserved for larger runs, while DTG printing is preferred for smaller orders.

How does screen printing work?

The screen printing process can be broken down into seven steps:

- Creating a Design: Digital files are printed onto transparent films, which serve as the basis for the stencil.

- Preparing the Screen: A screen corresponding to the design and fabric is selected, and a light-sensitive emulsion is applied.

- Exposing the Emulsion: The emulsion is exposed to light, hardening around the design areas.

- Creating the Stencil: The hardened emulsion is washed away, leaving a stencil in the shape of the design.

- Preparing for Printing: The screen is placed on a printing press, and the garment is positioned on a printing board under the screen.

- Pressing Ink Through the Screen: The screen is lowered, ink is applied, and a blade presses the ink through the stencil onto the T-shirt.

- Curing Ink: The ink is cured using a heat gun, heat press, flash dryer, or conveyor dryer to ensure durability.

Factors to Consider: DTG vs. Screen Printing

To decide between DTG and screen printing, consider the following factors:

Production Process

DTG printing is particularly advantageous for shorter print runs due to its streamlined process. Unlike screen printing, which requires the creation of multiple stencils and screens for each color in a design, DTG printing directly transfers digital images onto fabric. This eliminates the need for extensive setup, making it a more efficient option for custom or small-batch orders. The ability to print directly from digital files means that you can quickly transition from design to print, significantly reducing lead times and allowing for on-demand printing.

Screen printing, on the other hand, is more labor-intensive. Each color in a design requires a separate stencil and screen, and setting these up can be time-consuming. This makes screen printing less efficient for small runs, but it excels in high-volume production. Once the setup is complete, screen printing can produce a large number of T-shirts per hour, making it cost-effective for bulk orders. The initial setup time is offset by the speed and efficiency of printing large quantities, which is why many manufacturers still prefer screen printing for large-scale production.

Types of Design

DTG (Direct-to-Garment) printing and screen printing each have their strengths when it comes to design complexity and color usage:

DTG Printing: DTG printing excels when it comes to intricate designs with multiple colors and high resolution. This method directly applies ink from digital files onto fabric, allowing for detailed designs with smooth gradients, fine details, and a full spectrum of colors. Whether you’re reproducing artwork, photographs, or intricate patterns, DTG printing ensures that every detail is captured accurately and vividly. It’s ideal for custom designs that demand high-quality printing without the limitations of color count.

Screen Printing: Screen printing is well-suited for bold, simple designs with fewer colors. This method involves using separate screens and stencils for each color in the design, which makes it optimal for solid colors, large areas of color, and designs that don’t require complex gradients or fine details. Screen printing can achieve vibrant, opaque colors that stand out prominently on fabrics, making it popular for designs that emphasize boldness and clarity.

Printing Quality

When comparing DTG (Direct-to-Garment) printing and screen printing in terms of print quality:

DTG Printing: DTG printing generally delivers higher quality prints with sharper images and a full range of colors. This method utilizes advanced digital technology to directly apply water-based ink onto the fabric. It excels in reproducing intricate details, fine lines, and complex designs with smooth gradients. DTG printers can accurately render photographs, artworks, and designs that require precise color matching and high-resolution output. This makes DTG ideal for custom orders where print quality and detail are paramount.

Screen Printing: Screen printing is renowned for its ability to produce bright, opaque colors that stand out prominently on fabrics. However, it is limited in fine detail compared to DTG printing. Screen printing involves creating separate stencils (screens) for each color in the design and then pushing ink through these screens onto the fabric. This process results in solid, vibrant colors but may struggle with intricate details, small text, or designs that require subtle shading or gradients. Screen printing is best suited for bold, graphic designs with fewer colors and larger print runs.

Cost

DTG is cost-effective for small print runs due to its low setup costs. Screen printing becomes more economical for larger orders despite its higher initial setup costs.

Order Quantity

DTG provides flexibility with no minimum order requirements, making it ideal for small or custom orders. Screen printing is more suitable for bulk orders due to setup expenses.

Longevity

Screen printing tends to be more durable, with ink layers pressed deeply into the fabric. DTG prints are also long-lasting but may be less resistant to sunlight and washing over time.

Environmental Impact

DTG is more eco-friendly, using water-based inks and reducing waste through on-demand printing. Screen printing consumes more ink and energy, often leading to overproduction and waste.

By understanding these factors, you can make an informed decision on whether DTG or screen printing is better suited for your specific needs.

Tips for getting started with DTG printing

Are you excited to dive into the world of direct-to-garment (DTG) printing? Here are some practical tips to help get you started on the right foot:

Understand your design software

Familiarize yourself with popular graphic design software like Adobe Illustrator or Photoshop. Investing time in learning how to create detailed and visually appealing designs will pay off in the long run. These tools are essential for creating high-quality digital files for DTG printing.

Experiment with colors and textures

One of the strengths of DTG printing is its ability to handle designs with multiple colors and intricate details. Don’t be afraid to experiment with your palette. Complex gradients, large detailed images, and intricate designs can be achieved effortlessly with DTG printing, allowing your creativity to shine.

Consider the material

DTG printing performs best on 100% cotton materials. While it is possible to print on blends, the ink may not adhere as well to the non-cotton fibers. For the best results, choose high-quality cotton garments that will allow the ink to bond effectively.

Invest in quality equipment

While it might seem obvious, investing in a quality DTG printer is crucial. High-quality machines deliver superior results and are more reliable over time. Research different models and read reviews to ensure you’re making a sound investment.

Test prints

Before committing to a large print run, always make a test print. This step is essential to ensure that your design appears exactly as you imagined it on the fabric. Test prints allow you to make any necessary adjustments before producing a large quantity.

Maintenance is key

Regular maintenance of your DTG printer will ensure its longevity and optimal performance. Regularly clean the printer to prevent clogs and other common issues. Follow the manufacturer’s maintenance guidelines and schedule routine check-ups to keep your machine in top condition.