DTG Printing – Direct to garment Printing: A Comprehensive guide

Direct-to-Garment (DTG) printing is revolutionizing the custom apparel industry. This digital printing technology is transforming key elements such as quality, efficiency, and customization options. It offers a quick, user-friendly, and cost-effective solution for e-commerce retailers to produce and sell personalized t-shirts and other garments. If you’re an artist or creator eager to make your mark in the world of custom apparel, you’re in the right spot.

In this post, EmbroInk’ll dive deep into the ins and outs of DTG printing, providing you with a thorough understanding of how this innovative technology is revitalizing the custom apparel landscape.

What is DTG Printing?

Direct-to-Garment (DTG) printing is a technique for producing t-shirts by using a specialized digital printer to apply water-based inks directly onto fabric. Unlike other printing methods, DTG transfers inks straight onto the t-shirt without the need for a screen or paper as an intermediary.

DTG printers use digital files to source images for printing, allowing for a wide range of colors and a high level of resolution and detail. This method works well on various t-shirt fabrics, including cotton, polyester, and cotton/polyester blends, with natural fabrics like cotton being the ideal choice.

One of the key advantages of DTG printing is its eco-friendliness, thanks to its use of water-based inks and its capability to print on organic cotton. Additionally, since DTG printing operates from digital files, it can accommodate any quantity of t-shirts, from single units to large orders.

While DTG printers can be costly—often exceeding $10,000—you don’t need to invest in a printer to take advantage of DTG printing services. This accessibility makes direct-to-garment printing a viable option for small businesses and entrepreneurs looking to enter the custom apparel market.

Benefits of DTG Printing

Recognizing the distinct advantages of DTG printing can empower you to make an informed choice for your custom apparel needs. Here are some of the key benefits that are transforming the industry and enhancing creativity:

- High-Quality Prints: DTG printing delivers high-resolution prints with vibrant colors and crisp details, making it ideal for intricate designs that require color gradients or multiple hues.

- Efficiency for Small Orders: Unlike other printing methods, DTG is perfect for low-volume orders and one-off items, making it an excellent choice for start-ups and small businesses.

- Quick Turnaround: With no extensive setup required as in screen printing, DTG can produce orders in significantly less time, allowing for faster delivery.

- Unlimited Color Choices: DTG printing enables you to incorporate any number of colors into your design without incurring extra costs, providing greater flexibility for your creative vision.

- Eco-Friendly: Using water-based inks, DTG printing is more environmentally friendly than traditional plastisol inks commonly used in screen printing.

- Complete Customization: Since designs are digitally printed directly onto the garment, DTG technology allows for total customization, making it perfect for brands and artists looking to explore diverse designs.

Types of DTG Printers on the Market and the Materials and Inks They Use

The evolution of Direct-to-Garment (DTG) printing technology has led to a range of advanced printers that cater to different needs and budgets. Selecting the right DTG printer largely depends on your business type, professional requirements, and financial constraints. Here’s an overview of the various types available:

Entry-Level DTG Printers:

- Examples: Epson SureColor F2100, Brother GTX Pro

- Description: These printers are ideal for beginners or smaller businesses. They are cost-effective and deliver high-quality prints, though they may operate at a slower speed and offer a more limited color gamut.

Mid-Level DTG Printers:

- Examples: Anajet mPower, ColDesi M2

- Description: A practical choice for those needing faster turnaround times, these printers provide more consistent results and a broader color range compared to entry-level models.

Industrial DTG Printers:

-

- Examples: Kornit Avalanche HD6, Epson F3070

- Description: Designed for industry professionals handling large volume orders, these printers boast the highest production speeds, exceptional print quality, and superior consistency.

Inks and Materials

Regardless of the printer type, all DTG printers utilize water-based inks, which are more eco-friendly than traditional solvent-based inks. These inks are specially formulated to perform well on both light and dark fabrics, offering artists the freedom to create with a virtually unlimited color palette.

Fabrics Suitable for DTG Printing

DTG printing is highly versatile, accommodating a wide range of materials. The most preferred fabric is 100% cotton, as it absorbs water-based inks exceptionally well. However, cotton blends and polyester fabrics can also yield impressive results, making them viable options for various custom apparel projects.

How Does DTG Printing Work?

Direct-to-Garment (DTG) printing is a unique method that applies inks directly onto t-shirt fabrics, distinguishing it from traditional printing techniques that utilize screens or paper. This process employs a specialized inkjet printer designed to use water-based inks known as aqueous inks. Here’s a detailed breakdown of the four-step process involved in DTG printing:

Preparing Digital Art Files

DTG printers rely on digital art files to create designs. The best file formats for DTG printing include PSD and PNG, which support transparent backgrounds, but other common formats like JPG and TIFF are also acceptable.

Graphics design software like Photoshop typically uses the RGB (Red, Green, Blue) color model, whereas DTG printers operate using the CMYK (Cyan, Magenta, Yellow, Black) model. To bridge this gap, DTG printing software utilizes Raster Imaging Processor (RIP) software to convert RGB files into CMYK format for accurate color reproduction.

Pretreating and Curing T-Shirts

According to All Print Heads, DTG inks work optimally with natural fibers like cotton, bamboo, and hemp. To ensure the ink adheres correctly, a pretreatment process is applied to the t-shirt before printing. This involves applying a liquid solution that prevents white ink from soaking into the fabric, which could cause discoloration, and also stops it from smearing or blending with colored inks.

After applying the pretreatment solution, the shirt is cured using a heat press or air dryer. This step flattens the fabric fibers, creating a smoother surface for printing.

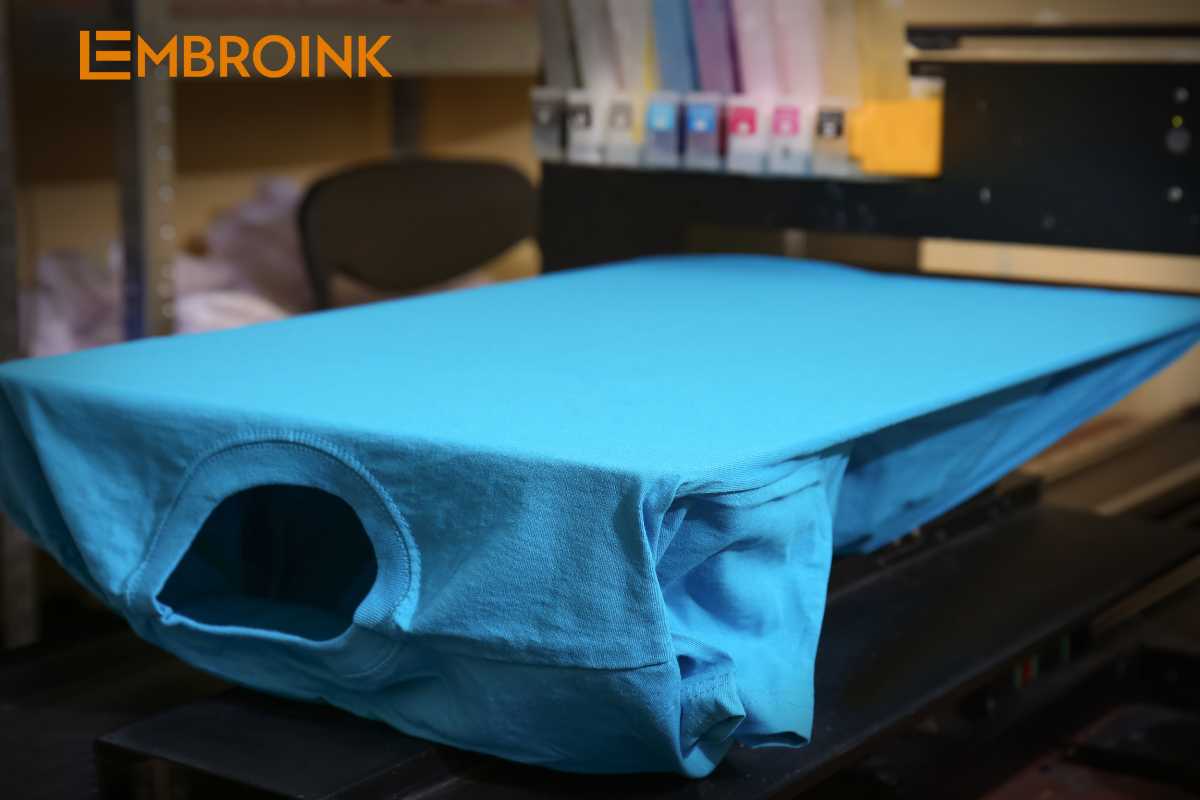

Printing on T-Shirts

Once the t-shirt is pretreated, it is placed on a flat platform called a platen. The platen secures the t-shirt in place, ensuring it remains flat and properly aligned for printing. Alignment can be achieved by matching the shirt’s neck collar, shoulder seams, or side seams to the platen. After alignment, the platen is fed into the DTG printer, where the design is printed directly onto the fabric.

Curing the Ink

After printing, the ink must be cured to securely adhere it to the garment, ensuring durability through repeated washings. Curing is typically performed using a heat press or a forced air dryer, solidifying the print and enhancing its longevity.

This step-by-step process illustrates how DTG printing combines advanced technology with precise techniques to produce high-quality custom apparel.

DTG vs. Screen Printing: Which Method is Better?

When deciding between Direct-to-Garment (DTG) printing and screen printing, the choice largely depends on your specific needs. DTG is typically better for short print runs, intricate designs, and sustainable practices, while screen printing excels with larger quantities and durability. To help you understand these methods further, let’s take a closer look at screen printing.

Screen Printing: An Overview

Also known as silk screen printing, screen printing is a technique where ink is applied to t-shirts through a mesh stencil. This indirect method contrasts with DTG, which applies ink directly to the fabric.

How does Screen Printing work?

The screen printing process consists of seven main steps:

- Creating a Design: This involves printing digital files onto transparent films, which serve as the stencil for the design.

- Preparing the Screen: A screen is selected based on the design and fabric type, then coated with a light-sensitive emulsion.

- Exposing the Emulsion: The screen is exposed to light, hardening the emulsion around the design shape.

- Creating the Stencil: After exposure, the hardened emulsion remains, and the unexposed areas are washed away, leaving the stencil.

- Preparing for Printing: The screen is placed on a printing press, and the garment is positioned beneath it.

- Pressing Ink Through the Screen: A blade or squeegee presses the ink through the stencil onto the t-shirt.

- Curing the Ink: Finally, the printed shirt undergoes curing using heat to ensure durability.

Factors to Consider: DTG vs. Screen Printing

When choosing between these two printing methods, consider the following aspects:

Production Process

DTG has the advantage for short print runs, as it eliminates the lengthy setup required for screen printing. Although screen printing can produce many t-shirts per hour, the preparation time makes it less efficient for small batches.

Types of Design

DTG technology excels with detailed designs that require multiple colors, whereas screen printing works best for simple, bold designs with fewer colors. Screen printing struggles with intricate details and photographic quality.

Printing Quality

According to Forbes Advisor, DTG generally provides superior quality. It prints high-resolution designs with sharp images, while screen printing, although vibrant, is limited to larger-scale details.

Cost

For smaller orders, DTG printing is typically more cost-effective due to lower setup costs. Screen printing becomes economical only for larger orders. The cost also increases with the number of colors in screen printing designs.

Order Quantity

DTG offers flexibility with order sizes, allowing for both small and large quantities without minimum requirements. Screen printing often imposes minimum order quantities.

Longevity

Screen printing has an edge in durability, as its thicker ink layers adhere well to fabric and resist fading over time. However, DTG prints are also designed to last.

Environmental Impact

DTG is more environmentally friendly, using less ink and generating less waste than screen printing. The latter often leads to overproduction and excess clothing waste. DTG aligns with sustainable practices, utilizing responsibly sourced materials and local production to minimize carbon emissions.

Ultimately, the choice between DTG and screen printing hinges on your specific needs regarding order size, design complexity, and budget. By evaluating these factors, you can determine which printing method best suits your project or business objectives.