Sublimation vs. DTG: A Print Showdown

It’s no secret that the best-looking tee in the room always grabs the spotlight. Maybe you’ve even thought about designing your own? Starting a custom apparel business can be challenging, but print-on-demand services have made the industry more accessible to everyone. These days, custom printing is something most people are familiar with. You might even know someone who has tried their hand at t-shirt printing or launched a custom printing business.

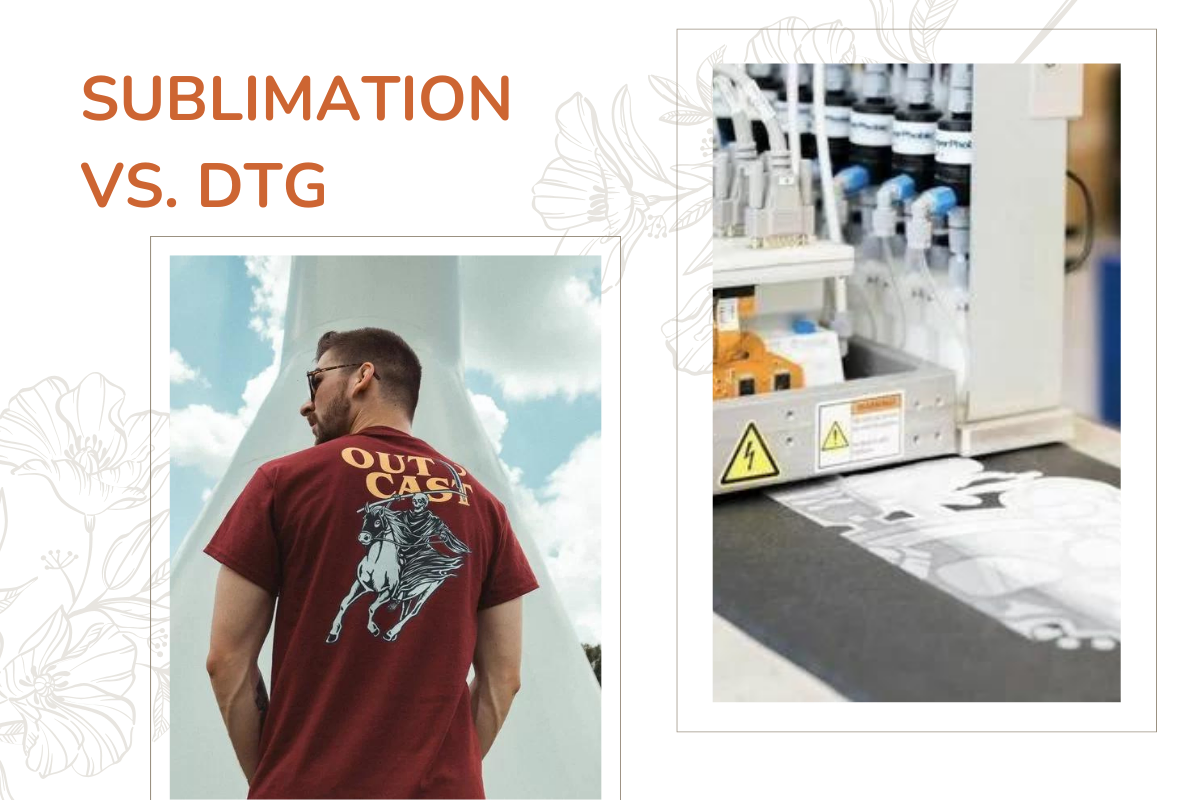

If you’re thinking about doing the same, it can feel a bit overwhelming at first. Different printing techniques are better suited for specific materials, designs, and business models. Today, EmbroInk dive into two popular printing methods to consider for your shop: sublimation and DTG. Comparing these options will help you make the best choice for your future online store.

The basics of Sublimation

Sublimation, also known as heat transfer printing, is a technique where designs are embedded directly into fabric fibers using a combination of ink, heat, and pressure. The outcome? Permanent, vibrant prints that resist fading and cracking over time, making sublimation ideal for all-over prints on sportswear, activewear, and polyester-based fabrics. It’s no surprise that this method has become a go-to in the print-on-demand industry.

However, the sublimation process is not without its challenges. It involves several steps, making it more time-consuming from start to finish.

Here’s a breakdown of the process:

- The design is first printed onto special paper using sublimation ink.

- The printed paper is then placed on the item you want to print on.

- Using a heat press, pressure and heat are applied to transfer the design.

- The heat causes the ink to turn into a gas.

- The gaseous ink penetrates the fibers of the product, creating a permanent, full-color print.

Sublimation isn’t limited to just custom t-shirt printing. This versatile technique can also be used to print on a wide range of items, including blankets, mugs, laptop covers, slippers, and even phone cases.

The basics of DTG Printing

Direct-to-garment (DTG) printing is a technique where ink is sprayed directly onto the fabric, allowing for precise reproduction of intricate designs with a soft finish. DTG is especially effective on natural materials like cotton, as the fabric absorbs the ink, resulting in a vibrant and durable print.

Compared to sublimation, DTG is a more straightforward process, requiring fewer steps and less specialized equipment to produce stunning designs.

Here’s a step-by-step look at how DTG printing works:

- The design is first uploaded to a computer and adjusted as needed.

- A pre-treatment is applied to the garment to help the ink bond with the fabric.

- The garment is then loaded into the printer, where the ink is sprayed onto the fabric to create the design.

- Finally, the printed garment is placed in a heat press or conveyor dryer to cure the ink, making the design permanent.

DTG printing is one of the most popular on-demand printing methods. It allows for quick production of one-off prints, taking just a few minutes per item. Additionally, DTG printing is cost-effective, as it eliminates the need for expensive setups like printing plates or screens, which are commonly required in traditional printing methods.

Sublimation vs. DTG—Let the battle begin

Now that we’ve covered the basics of sublimation and DTG printing, it’s time to dive deeper into what sets these methods apart and, more importantly, which one is the right choice for your business.

Print quality and durability: Built to Last

When it comes to print quality, sublimation is hard to beat. Since the ink is embedded directly into the fabric fibers, the design becomes a permanent part of the garment. This means your prints won’t fade, crack, or peel over time. Sublimation excels at producing vibrant, intricate designs with sharp, detailed lines.

DTG printing also delivers impressive print quality. While a freshly printed DTG design might feel slightly rough or rubbery, this texture softens after a few washes. DTG is a great option for colorful, detailed designs, but the prints may be slightly less vibrant on dark or brightly colored garments because the fabric absorbs more of the ink.

Overall, sublimation prints tend to be more durable than DTG prints. However, if you follow proper care instructions, DTG prints can still look fantastic even after multiple washes.

Basic Care Tips:

- Use a gentle wash cycle for printed fabrics.

- Avoid fabric softeners and bleach.

- Refrain from ironing directly on the prints.

Print Complexity: Unleashing Creativity

Sublimation is a versatile printing technique that handles complex designs with ease. Whether you’re working with detailed patterns, vibrant colors, gradient shades, or even digital photos, sublimation can bring your creative ideas to life with stunning accuracy.

DTG printing, while also capable of producing colorful and intricate designs, has one key consideration: the fabric’s ability to absorb ink. Gradient prints can be challenging with DTG, and some designs may not have the same level of clarity as those produced through sublimation. Nonetheless, DTG is still a solid choice for most design ideas, offering a vivid and diverse final product.

In summary, both sublimation and DTG have their strengths, and the choice between them will depend on your specific needs, the materials you’re working with, and the type of designs you want to create.

Color Vibrancy: Enough Zing to Make a Lemon Jealous

When it comes to color vibrancy, both sublimation and DTG have their strengths. Sublimation excels in producing multiple color designs and gradients, utilizing the CMYK color model—cyan, magenta, yellow, and black. Since sublimation is typically done on light-colored fabrics, the white areas in your design will remain the color of the garment. However, sublimation has its limitations: it doesn’t support specialty inks or effects like glitter.

DTG also uses the CMYK color model but operates a bit differently. When printing on colorful or black garments, a white base layer is typically applied first to ensure the colors stand out, though this step is skipped when printing on white fabrics. Since the ink is absorbed by the fabric, DTG prints can sometimes appear slightly less vibrant, especially on darker garments.

Fabric Suitability: Finding the Perfect Match

Sublimation is best suited for synthetic fabrics, which makes it ideal for sportswear. Polyester blends, nylon, spandex, neoprene, and other synthetic materials work exceptionally well with sublimation. While you can technically sublimate on cotton, the results are far superior on synthetic fabrics. Additionally, sublimation isn’t limited to clothing; it can also be used on ceramic and enamel mugs, phone cases, and various other items.

DTG printing, on the other hand, shines on natural fabrics like cotton, linen, and bamboo. The ink bonds better with these materials, resulting in vibrant and durable prints. While DTG can be used on other types of fabrics, the composition of the material can affect how well the ink is absorbed, potentially altering the look and feel of the final product.

Eco-Friendliness: Printing with a Conscience

If sustainability is a priority, sublimation is a strong contender. The inks used in sublimation are non-toxic, meaning they don’t release harmful chemicals into the environment. Additionally, sublimation requires minimal water compared to other dye transfer techniques, making it a more eco-friendly choice.

DTG also ranks high in eco-friendliness. One of its major advantages is that it’s well-suited for printing one-off items, which helps reduce overproduction and textile waste. Since you can order exactly what you need, there’s little to no waste involved, making DTG a responsible choice for environmentally conscious businesses.

On-Demand Fulfillment

When it comes to on-demand fulfillment, both sublimation and DTG are excellent choices. The key is selecting the right provider that aligns with your business needs.

Upfront Investment

If you’re considering doing the printing yourself, it’s important to factor in the upfront costs associated with each method. Sublimation can be more cost-effective for larger orders due to its relatively simple setup. You’ll need an inkjet printer, transfer paper, a heat press, and specific sublimation inks. While these items do require an initial investment, the overall cost is generally lower compared to DTG.

DTG printing, on the other hand, often requires a higher upfront investment. DTG printers are typically more expensive, and the process also involves additional expenses like pretreatment solutions, curing equipment, and regular maintenance supplies to ensure high-quality results. This makes DTG a better option for smaller quantities or businesses focusing on one-off or limited-run designs.