Selecting the ideal T-Shirt materials for prints

Before bringing your t-shirt designs to life, choosing the T-Shirt materials is essential. You might be wondering: Does fabric weight really matter? Do customers prefer a silky drape or a snug fit? And which printing method—DTF, DTG, or embroidery—should you opt for? In this comprehensive t-shirt fabric guide, we’ll explore the most popular fabric types, different printing methods, and which fabrics work best for each. We’ll also help you select materials that will not only meet but exceed your customers’ expectations. Let’s join with EmbroInk.

Stunning designs alone won’t make your custom t-shirts sell. Your customers are seeking specific fabric qualities for different occasions. For instance, heavyweight fabrics are ideal for streetwear brands, while athletic wear should be lightweight and moisture-wicking. Your target audience might also care about how the fabric is sourced. In this case, it’s important to consider the production process and environmental impact. Let’s dive into the most popular materials, starting with the all-time favorite—cotton.

Cotton T-Shirt materials

Cotton has been used for thousands of years and remains the most popular fabric in the textile industry. Made from natural fibers spun into yarn, cotton seems like a sustainable choice—but the reality is more complex (we’ll explore that later).

Characteristics of Cotton

Cotton is known for being soft, breathable, biodegradable, absorbent, durable, and affordable. It also holds dyes exceptionally well, making it one of the best materials for t-shirt printing. No wonder it’s the top choice among our customers.

Pros of Cotton

As mentioned, cotton is incredibly breathable and has excellent moisture-absorbing properties, making it the ideal fabric for hot and humid weather. When you sweat, cotton absorbs the moisture and allows it to evaporate, keeping you feeling fresh and cool.

Beyond its practicality, cotton is renowned for its softness and versatility. This ultra-comfortable material is suitable for any occasion. You can dress up a cotton t-shirt under a vest, layer it under a wool sweater to avoid itchiness, or wear it on its own.

Cotton is also hypoallergenic, similar to materials like silk, bamboo, and eucalyptus, making it a great option for children’s clothing or for those with sensitive skin.

Cons of Cotton

On the downside, pure cotton isn’t the best choice for winter, especially if you’re likely to sweat. A wet cotton shirt in the cold is far from comfortable. However, cotton blends can offer better insulation in colder weather.

Cotton t-shirts also tend to wrinkle easily, and the fabric is more prone to wear and tear compared to synthetic blends. Additionally, cotton is sensitive to color fading, but with proper care, you can extend its lifespan significantly.

It’s important to note that cotton clothing can shrink when washed, so always follow the care instructions on the fabric label. Pre-shrunk cotton will minimize shrinkage.

For a detailed comparison, check out our Guide to Cotton, Polyester, and Blended Fabrics.

Customization Methods for Cotton T-Shirts

Let’s start by exploring the best customization methods for cotton t-shirts before diving into the different types of cotton (because not all cotton is created equal).

DTG Printing

Direct-to-garment (DTG) printing involves spraying ink directly onto the fabric, allowing for high-quality, full-color prints that are soft, breathable, and durable. This method is ideal for creating colorful designs, graphics, text, and more. With proper care, your DTG-printed t-shirts can last a long time.

DTG printing works particularly well with cotton, bamboo, or other natural materials due to their excellent absorption properties. However, because a lot of the ink is absorbed by the fabric, prints may appear less vibrant on dark or highly colored garments.

DTF Printing

Direct-to-film (DTF) printing is a newer technique that’s quickly gaining popularity in the print-on-demand industry. DTF offers vibrant colors, low production costs, and the ability to print on both light and dark garments.

Unlike DTG, DTF works on a wide range of materials, including polyester, nylon, fleece, and cotton. The process involves printing the design onto a special transfer film using water-based inks, coating it with adhesive powder, and then transferring it onto the fabric using a heat press.

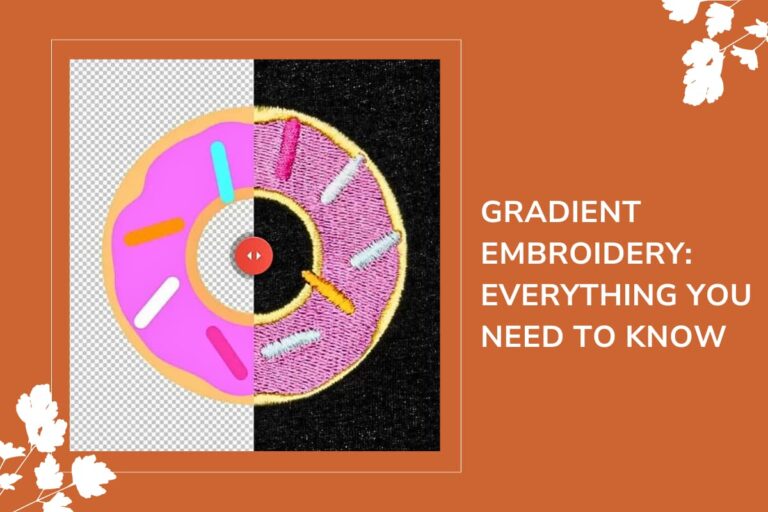

Embroidery

Cotton t-shirts are perfect for custom embroidery thanks to their tightly woven fabric. For the best results, choose a moderately heavy cotton fabric that won’t snag around the embroidered design or be too thick for embroidery machines to stitch through.

Embroidered t-shirt designs are incredibly versatile, making them a great option for your t-shirt business and a way to appeal to a wide range of customers. If you need inspiration, check out our Step-By-Step Guide to Embroidery Designs.

Types of Cotton T-Shirts

If you’ve ever noticed that not all cotton t-shirts feel the same, it’s because the production process varies. Some cotton shirts are soft and lightweight, while others are thicker with a more textured weave. These differences are due to the type of cotton and how it’s processed. Here are the four main categories of cotton t-shirts:

100% Cotton

When a t-shirt is labeled as 100% cotton, it typically refers to regular cotton, also known as carded open-end (COE) cotton. This type of cotton is produced by spinning raw cotton into yarn through the carded open-end process.

Regular cotton t-shirts are thicker, heavier, and not as soft as other types of cotton. They’re perfect for casual wear or streetwear and are an excellent choice for DTG prints or embroidered designs. Additionally, 100% cotton is the most affordable option due to its lower production costs.

Ring-Spun Cotton

Ring-spun cotton is made by wrapping cotton fibers tightly around a spindle, aligning and binding them together. This process creates a fabric that is softer and smoother than COE cotton, offering an upgrade in quality and comfort for only a slightly higher price.

The fine fibers of ring-spun cotton allow prints to adhere more evenly, resulting in a beautiful, long-lasting design. The fabric weight is similar to regular cotton, but you’ll enjoy greater softness and the same level of insulation.

Combed Ring-Spun Cotton

Combed ring-spun cotton goes through an additional step after the ring-spinning process. The cotton is combed to remove impurities and any short fibers that might stick out of the yarn. This results in a fabric that is silky soft and incredibly smooth on the skin, making it the highest quality cotton—and also the most expensive.

While the combing process reduces impurities, it also creates more waste, as some fibers are discarded. However, the high-quality yarn produced by this method means that garments tend to last longer. With fewer impurities, combed ring-spun cotton provides the smoothest surface for printing, making it the top choice for brands focused on quality and luxury.

Organic Cotton

For those who prioritize sustainability and ethical farming, organic cotton is an excellent choice. Organic cotton is grown without genetically modified organisms (GMOs), pesticides, or harmful chemicals, reducing environmental impact and promoting better working conditions.

The great thing about organic cotton is that it can also be ring-spun and combed, so you don’t have to compromise on comfort or quality when choosing more environmentally friendly t-shirts.

Cotton and Sustainability

Cotton’s sustainability is a topic of debate. On the positive side, farmers use the entire cotton plant—the seeds are processed into oil for food and cosmetics, while the fibers are used for textiles or even coffee filters.

However, traditional cotton farming consumes large amounts of water and requires pesticides, which can be harmful to both the environment and workers. For more sustainable options, check out our Sustainable Fabrics Guide, which lists alternatives to conventional cotton.

Polyester T-Shirt materials

Polyester, derived from its technical name polyethylene terephthalate (PET), is the world’s most popular synthetic fabric. Made primarily from petroleum, a natural but non-renewable resource, polyester can also be produced from recycled plastic, making it a more sustainable option.

Characteristics of Polyester

Polyester is lightweight, highly durable, and resists fading and shrinking when properly cared for. While not inherently elastic, it gains flexibility when blended with materials like elastane. Though polyester is breathable, it doesn’t offer the same level of breathability as cotton.

Pros of Polyester

One of polyester’s standout features is its wrinkle resistance—perfect for those who prefer to skip ironing. Polyester also dries quickly and, if made from high-quality thread, resists wear and tear over time. These qualities make polyester t-shirts easy to maintain and ideal for athletic wear.

Thanks to its moisture-wicking properties, polyester is great for sports. The fabric traps sweat against the skin and allows it to evaporate instead of absorbing it, keeping you dry and comfortable during physical activity. This makes polyester shirts suitable for both warm and cool conditions.

Cons of Polyester

However, polyester has some downsides. It’s non-biodegradable, meaning a polyester t-shirt can take up to 200 years to decompose unless recycled. The manufacturing process also relies on fossil fuels and involves significant chemical use.

On the plus side, recycled polyester is created by melting down old plastic and spinning it into new fibers. It takes about five plastic bottles, which might otherwise end up in a landfill, to produce one t-shirt.

Lastly, polyester may not be the best choice for those with sensitive skin, as it can sometimes cause irritation. However, most people find it comfortable to wear.

Customization Methods for Polyester T-Shirts

Polyester, especially when blended with other synthetic fibers, offers unique customization opportunities, particularly with sublimation printing, which sets it apart from other fabrics.

Sublimation Printing

Sublimation is a relatively new printing method that allows designs to be printed all over a garment. This technique is ideal for creating vibrant, full-coverage prints. However, sublimation ink doesn’t bond well with natural fibers like cotton, making polyester the go-to fabric for this method. If you’re planning to start a print-on-demand business focusing on eye-catching, all-over t-shirt designs, polyester is your best choice.

Polyester and Sustainability

From a sustainability standpoint, polyester garments are incredibly durable and require minimal water, energy, and heat for cleaning, contributing to their long lifespan. However, the downside is that polyester can take up to 200 years to decompose.

On the bright side, because polyester garments last so long, they don’t have to be discarded. You can repurpose them by adding new prints, altering them into different styles, or donating them to thrift stores.

For a more eco-friendly option, consider choosing polyester made from recycled plastic. This approach helps reduce waste by turning old plastic into new, wearable fabric.

Fabric Blends

Blending multiple fabrics together is a fantastic way to create textiles with unique properties. Today, most clothing is made from a mix of different fabrics, making it essential to explore fabric blends in any comprehensive t-shirt fabric guide.

Characteristics of Fabric Blends

The large-scale blending of fabrics began in the 1980s, driven by textile scientists aiming to develop the most comfortable materials for any occasion. Blending fabrics can enhance their texture, durability, and create the perfect surface for unique prints.

Advantages of Fabric Blends

Blending synthetic materials with natural fibers offers several benefits, including increased breathability, fewer wrinkles, better insulation, and reduced costs. Blended fabrics also dry faster than pure cotton t-shirts.

The combination of multiple fabrics can also improve their texture. For instance, mixing rayon with cotton enhances softness and adds a subtle sheen, improving both the appearance and feel of the fabric.

In terms of print designs, fabric blends can produce intriguing cross-dye effects. One fabric may absorb dye more vividly, while the other retains its natural color, creating a distinctive look that can be a plus or minus depending on your design goals.

Disadvantages of Fabric Blends

While blending fabrics can increase durability, you could also achieve this by simply choosing a more durable fabric from the start. The choice depends on the specific properties you want your t-shirt to have.

However, adding synthetic fibers to natural materials can reduce their natural benefits, such as hypoallergenic qualities, especially since some synthetic materials can trigger allergic reactions.

Additionally, fabric blends can complicate garment maintenance and washing. If you run a print-on-demand store, it’s crucial to inform customers about the specific care requirements for each garment to ensure longevity.

Customization Methods for Blended T-Shirt Fabrics

While sublimation printing is ideal for 100% polyester or polyester-spandex blends, other customization methods like Direct-to-Garment (DTG) printing, Direct-to-Film (DTF) printing, and embroidery are perfect for t-shirts made from blended fabrics.

Types of Fabric Blends

Blended fabrics typically combine two or three different fibers. Tri-blend fabrics are a popular example, often made of polyester, cotton, and rayon. The specific ratio of these fibers varies, with a common polyester-cotton blend being 65% polyester and 35% cotton.

Tri-Blend

A common tri-blend consists of polyester, cotton, and rayon, typically in a 50/25/25 ratio. While polyester and cotton are well-known, rayon is a semi-synthetic fiber derived from regenerated cellulose from natural sources like wood. Rayon, also known as viscose, can mimic natural fibers such as silk, cotton, wool, or linen, which is why it’s often referred to as artificial silk.

This tri-blend is beloved for its cozy feel and loose weave, making it perfect for creating DTG prints with a vintage aesthetic.

Polyester and Spandex Blends

Polyester alone doesn’t offer much natural stretch, which is why it’s often blended with spandex (also known as elastane or lycra). Spandex is renowned for its elasticity, and when combined with polyester, it produces t-shirts that are not only silky and smooth but also durable and stretch-resistant, making them ideal for activewear.

Cotton-Polyester Blends and Others

Have you ever noticed that gray clothes tend to be more comfortable? That’s because gray fabric is often a mix of different fibers with varying color grades, creating a shimmering, mottled effect known as melange or heather fabric. For instance, a white Women’s Relaxed T-Shirt from Bella + Canvas might be 100% combed ring-spun cotton, but in Athletic Heather, it would be 90% cotton and 10% polyester. Other heather colors might have a 52% cotton and 48% polyester composition.

Sustainability of Spandex and Rayon

Spandex (Elastane)

Spandex, like polyester, is petroleum-based and not the most sustainable fabric. However, efforts are being made to reduce its environmental impact. Its incredible stretch and resilience make it valuable in textile manufacturing, offering garments that are durable and movement-friendly.

Rayon (Viscose)

Rayon is made from renewable natural resources and is biodegradable. However, traditional production methods involve the use of toxic chemicals to convert cellulose into fabric. It’s important to ensure that the production process is ethical and uses a closed-loop system to minimize environmental harm.

Overall, choosing the right blend depends on the desired balance between comfort, durability, and environmental impact.

T-Shirt materials and Yarn Count: Why They Matter

Fabric weight and yarn count play significant roles in determining the quality and characteristics of t-shirts. They influence everything from the feel of the fabric to how it holds custom designs.

Fabric Weight

Fabric weight, measured in ounces per square yard or grams per square meter, affects the t-shirt’s thickness, drape, and durability. Here’s how it impacts your t-shirts:

- Lighter Fabrics: These are usually softer and more comfortable for everyday wear, especially in hot weather. They’re also more compact, making them ideal for travel as they take up less space. Common lighter fabrics include polyester and combed ring-spun cotton.

- Heavier Fabrics: These tend to be more durable and provide better insulation. They’re often used for garments that need to be more robust or for cooler climates. Examples include carded open-end (COE) cotton and linen.

Impact on Custom Designs:

- Heavier Fabrics: Custom prints on heavier fabrics may appear more textured. The thickness of the fabric can give a distinct tactile quality to the design.

- Lighter Fabrics: These are better suited for detailed and smooth prints. The finer texture allows for more precise and vibrant designs.

Yarn Count

Yarn count measures the fineness or thickness of the thread used to make fabric. It’s calculated by determining how many threads, each 840 yards long, are needed to weigh one pound.

- Higher Yarn Count: A higher number (e.g., 30/1) means the yarn is finer, resulting in a lighter, softer fabric. This creates a smooth finish and is often used for finer, more delicate t-shirts.

- Lower Yarn Count: A lower number (e.g., 18/1) indicates thicker, heavier yarn, leading to a more substantial and durable fabric.

Understanding Yarn Count:

- 30/1 Yarn Count: Requires 30 threads of 840 yards to make one pound of yarn. This typically results in a lighter and finer fabric.

- 18/1 Yarn Count: Requires fewer threads to make one pound, leading to a heavier and coarser fabric.

In summary, fabric weight and yarn count directly affect the feel, durability, and appearance of your t-shirts, as well as how they handle customization. Whether you prefer a lightweight, soft feel or a heavier, more durable fabric will depend on your specific needs and preferences.